[fusion_builder_container hundred_percent=”no” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” border_size=”” border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=””][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ spacing=”” center_content=”no” hover_type=”none” link=”” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_position=”left top” background_repeat=”no-repeat” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” padding=”” dimension_margin=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” last=”no”][fusion_title margin_top=”” margin_bottom=”10px” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” size=”1″ content_align=”left” style_type=”default” sep_color=”#fffcfc”]

Quality

[/fusion_title][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent=”no” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” border_size=”” border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=””][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ spacing=”” center_content=”no” hover_type=”none” link=”” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_position=”left top” background_repeat=”no-repeat” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” padding=”” dimension_margin=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” last=”no”][fusion_title margin_top=”” margin_bottom=”10px” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” size=”2″ content_align=”left” style_type=”default” sep_color=””]

QUALITY ASSURANCE

[/fusion_title][fusion_text]

At Autocast, extensive quality control procedures ensure repeatable parts and consistent subassemblies. Our Quality Management Program contains all the elements needed to meet the demands of quality-conscious companies. Beginning with the initial part design, quality is woven into the fabric of our entire operation.

[/fusion_text][fusion_title margin_top=”” margin_bottom=”10px” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” size=”2″ content_align=”left” style_type=”default” sep_color=””]

CORPORATE QUALITY POLICY

[/fusion_title][fusion_text]

- Provide our customers with zinc and aluminum castings and assemblies that meet or exceed customer specified requirements.

- Ship customer the correct product on time following all specified shipping requirements.

- Continually improve processes to enhance customer satisfaction and to ensure company viability.

- Conform to the established QMS based on ISO 9001:2015 and IATF 16949 requirements

QUALITY ASSURANCE

At Auto Cast, extensive quality control procedures ensure repeatable parts and consistent subassemblies. Our Quality Management Program contains all the elements needed to meet the demands of quality-conscious companies. Beginning with the initial part design, quality is woven into the fabric of our entire operation.

CORPORATE QUALITY POLICY

- Provide our customers with zinc and aluminum castings and assemblies that meet or exceed customer specified requirements.

- Ship customer the correct product on time following all specified shipping requirements.

- Continually improve processes to enhance customer satisfaction and to ensure company viability.

- Conform to the established QMS based on ISO 9001:2015 and IATF 16949 requirements

AWARDS

2013 GM Supplier Quality Excellence Award

2012 GM Supplier Quality Excellence Award

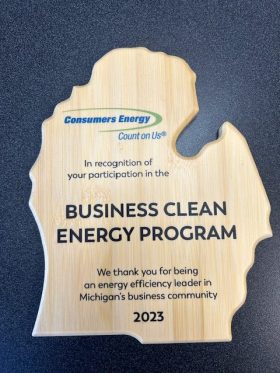

Consumer Energy 2023

Business Clean Energy Program

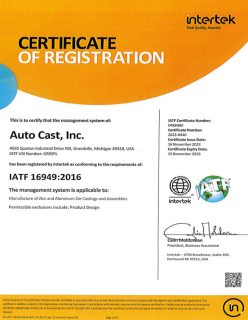

Certificate of registration

Auto Cast, Inc.

4565 Spartan Industrial Drive SW, Grandville, Michigan, 49418, USA

has been registered by Intertek as conforming to the requirements of:

IATF 16949:2016

The management system is applicable to:

Manufacture of Zinc and Aluminum Die Castings and Assemblies

Permissible exclusions include: Product Design

CORPORATE QUALITY POLICY

- Provide our customers with zinc and aluminum castings and assemblies that meet or exceed customer specified requirements.

- Ship customer the correct product on time following all specified shipping requirements.

- Continually improve processes to enhance customer satisfaction and to ensure company viability.

- Conform to the established QMS based on ISO 9001:2015 and IATF 16949 requirements

AWARDS

2013 GM Supplier Quality Excellence Award

2012 GM Supplier Quality Excellence Award

Certificate of registration

Auto Cast, Inc.

4565 Spartan Industrial Drive SW, Grandville, Michigan, 49418, USA

has been registered by Intertek as conforming to the requirements of:

IATF 16949:2016

The management system is applicable to:

Manufacture of Zinc and Aluminum Die Castings and Assemblies

Permissible exclusions include: Product Design